Cooney

Thermo-Pack

Steam to Heating Hot Water Heat Exchanger

Ultra-efficient steam to domestic hot hater heat exchanger. The Cooney Thermo-Pack’s sub-cooling design can help increase efficiency and reduce energy costs in a compact vertical footprint.

System Benefits

- Efficiency – condensate subcooling using sensible heat from condensate

- Reduces maintenance costs of condensate

- Small footprint compared to typical shell & coil

- Heat exchangers can be manifold together for unlimited capacity

- Control panel and integral sensing points allow precise control of discharge water temperatures

- V-Ball Control Valve with 300:1 turndown – can accommodate up to 300 LB steam without the need for a pressure-reducing valve

- Reduced maintenance costs of condensate pumps due to lower condensate temperatures

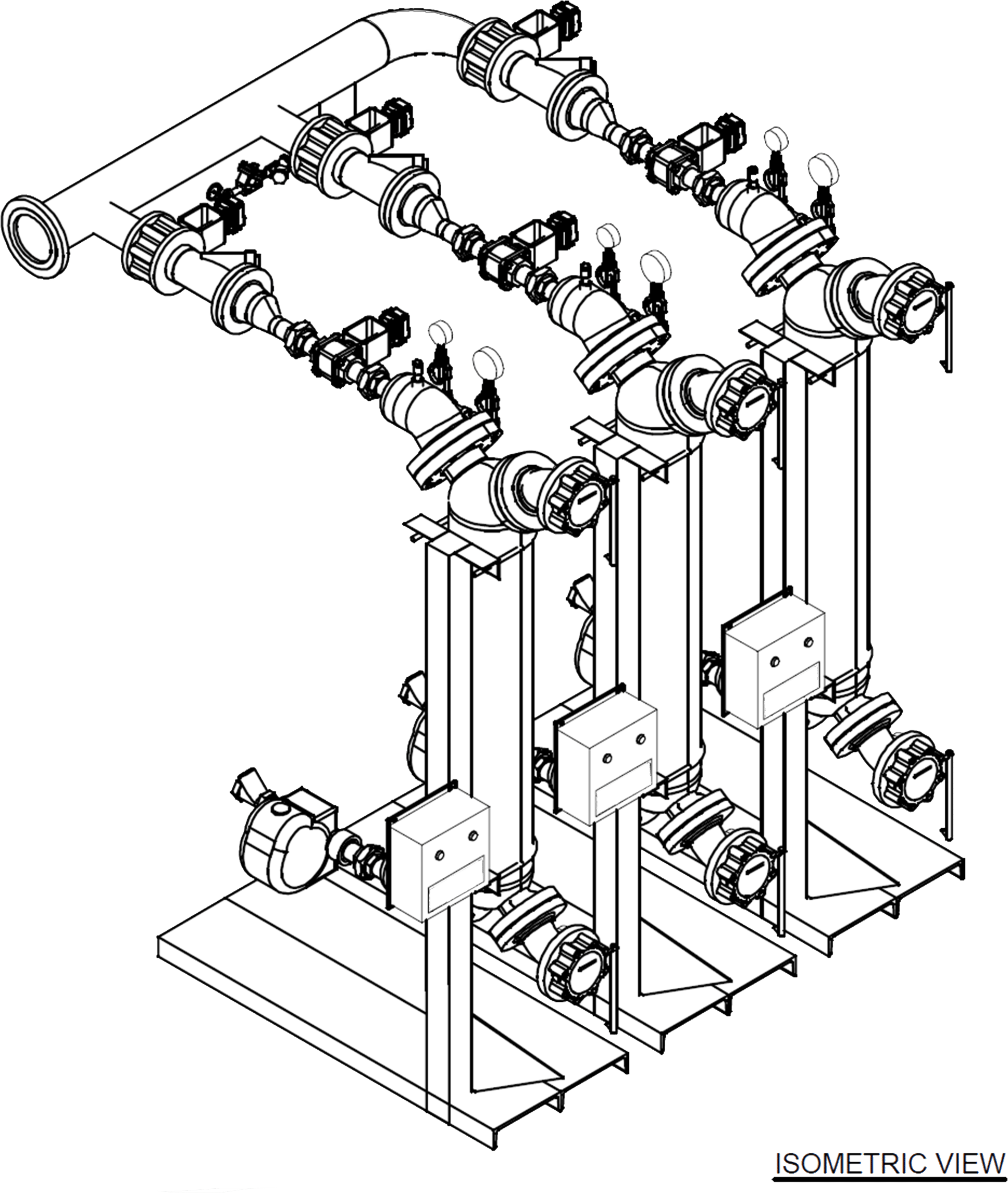

Standard Components

- 316L Stainless Steel Shell & Coil Heat Exchanger

- V-Ball Control Valve

- Pressure / Temperature Relief Valve

- Inlet Y-Strainer

- Recirculating Pump

- Painted Carbon Steel Base Plate and Frame

- Gravity Condensate Drainage Standard

Energy Savings

4-Week Savings of a Cooney Thermo-Pack Compared to a Shell & Tube Heat Exchanger*

*Based on steam pressure of 35 PSIG, 1,000 lbs/hour at a cost of $25 per Therm*

Interested in calculating your facility’s ROI? Contact us today for your own energy analysis.

Custom Solutions

Sick of stock units?

Do you need a hassle-free solution with the newest technology?

Invest in a Thermo-Pack and upgrade your hot water heat exchanger today!

At Cooney Engineered Solutions, we understand that different projects require different solutions. That’s why we provide personalized and customized Cooney Thermo-Pack options designed to meet your specific hot water heating needs and requirements. Let’s collaborate to engineer a solution that perfectly fits your project.

Skid Dimensions

Need to fit into limited existing space? We can adjust the skid dimensions to conform to locations with restricted space.

Outlet Orientations

We can adjust outlets to best fit your application making them easily accessible and saving you installation costs.

Adjustable Equipment Elevations

For areas with restricted headroom, we can usually adjust equipment elevations to fit your space.

Base Plate & Frame

Optional 316L SS base plate and frame.

Control Valve / Package

Variety of control options available per facility’s specifications and requirements. Up to 300-1 turndown control available. Pneumatic control valves also available.

Pressure Motive / Pump Traps

Gravity condensate drainage standard. Pump traps are available if condensate needs to be lifted.

Steam Shut Off Safety Valve

Available for an added level of steam safety protection.

Full Glycol Preheat Skids Available

Custom Heat Exchanger Solutions for Unique Projects

All heating hot water Cooney Thermo-Packs are customized to fit your specific application including elevations, piping, materials, components, and more. Cooney Engineered Solutions will be there for you throughout the entire process including:

- Consultation

- Initial Site Visit

- Customization

- Design

- Construction

- Start-Up

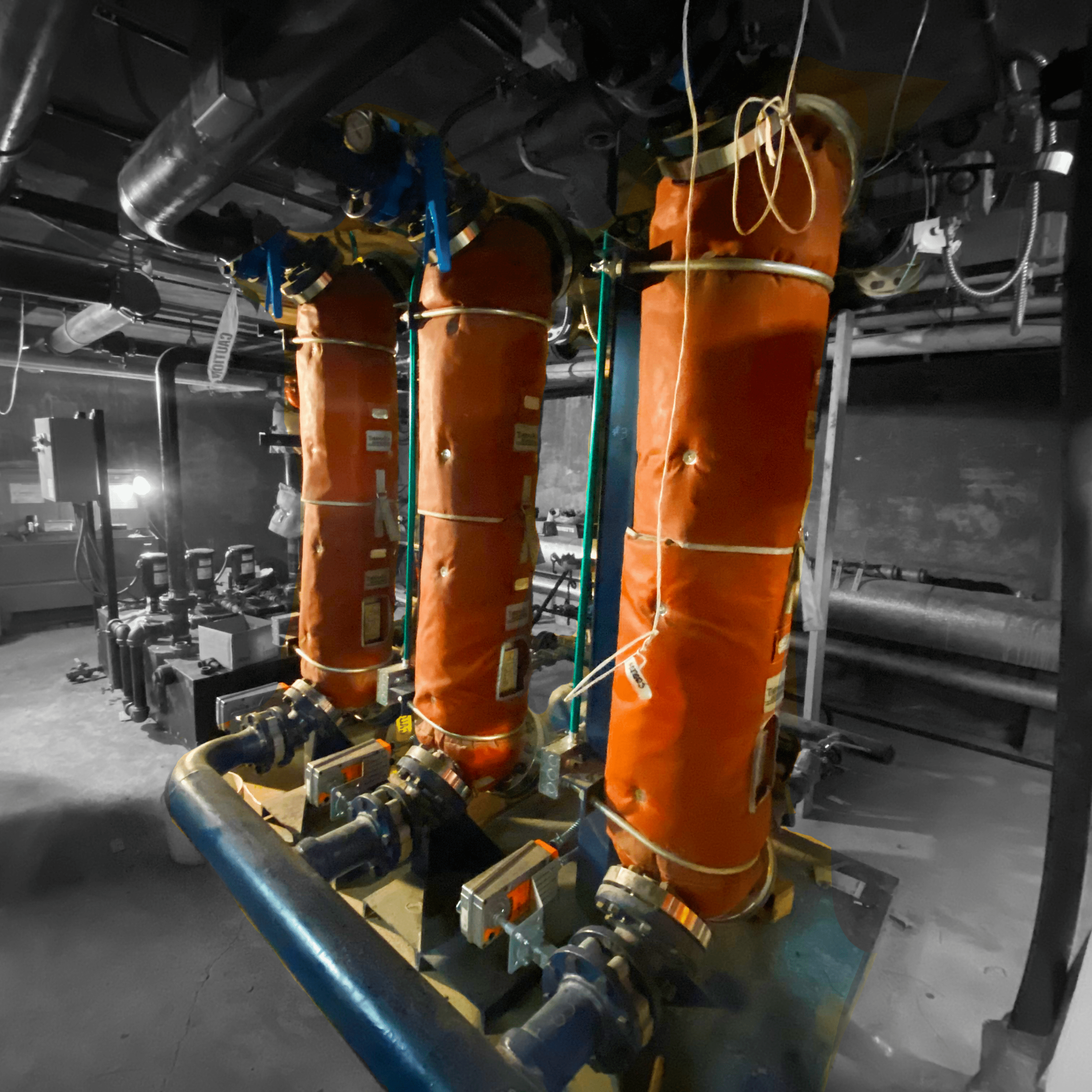

Cooney Thermo-Pack at Cornell University, Mary Donlon Hall

Ultra-Efficient Cooney Thermo-Pack Saves Energy & Reduces Maintenance

Are you looking for a way to maximize efficiency? Look no further than the Cooney Thermo-Pack: an ultra-efficient steam-to-hot water heat exchanger. Our cutting-edge heat exchanger transforms steam to hot water, offering energy savings and reduced maintenance, all while taking up minimal space. Let our team of experts help you get the most out of this incredible new system. Upgrade your facility’s hot water generation with the innovative Cooney Thermo-Pack today, and learn more about our skids for domestic hot water heat exchangers!

The Cooney Thermo-Pack is here to maximize your building’s energy efficiency. The efficient design of our steam heat exchanger for hot water allows it to utilize cross-counterflow subcooling, capturing both sensible and latent heat from the steam condensate. This innovative system takes up minimal space while still providing maximum energy savings and reducing maintenance costs. Our hot water heat exchangers are a true testament to our engineering expertise.

Looking to Install a New Steam to Heating Hot Water Exchanger?

The Cooney Thermo-Pack is an incredibly simple system to operate and features advanced controls. Its flexible design allows it to be integrated into existing steam systems or utilized in new builds, with the ability to adjust equipment elevations, skid dimensions, and piping orientations as needed. Not only does this make installation costs more manageable, but it also ensures that the unit can fit into tight spaces with ease. Unlock all the energy and maintenance savings available through our ultra-efficient steam heat exchanger for hot water and upgrade your building’s hot water generation today!

Contact Cooney Engineered Solutions for the Top Hot Water Heat Exchangers

Are you looking for a high-performance steam-to-hot water heat exchanger with minimal upkeep? The Cooney Thermo-Pack is 10-15% more efficient than its shell and tube counterparts, requires minimal maintenance, and offers optimized performance. Contact us today for more information about installation options and pricing so you can start taking advantage of its benefits right away.

Testimonials

Cornell University Case Study

Learn how Cornell University is utilizing Cooney Thermo-Pack’s to provide reliable, efficient hot water to residents in their North Campus.

“Cooney Engineered Solutions worked with us and created what we wanted. The condensate sub-cooling and how cool we can get the condensate is great. We’re getting more heat and that’s a big factor with any kind of hot water conversion, to be more efficient”

Request a Quote

Save energy, space and money.